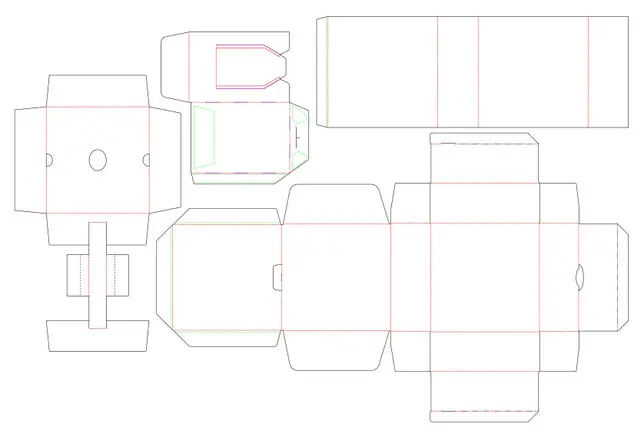

The initial phase of Prealpi's operations takes place in the technical office where people who have perfect knowledge of the company's production cycle interpret customer needs and ideas in a way that can be "industrialised." This office is where thoughts take shape and are scaled up, the place where every project begins to materialise. Through technical drawings, prototypes, and tests, the materials and production cycle necessary for the manufacturing of customised boxes are defined.

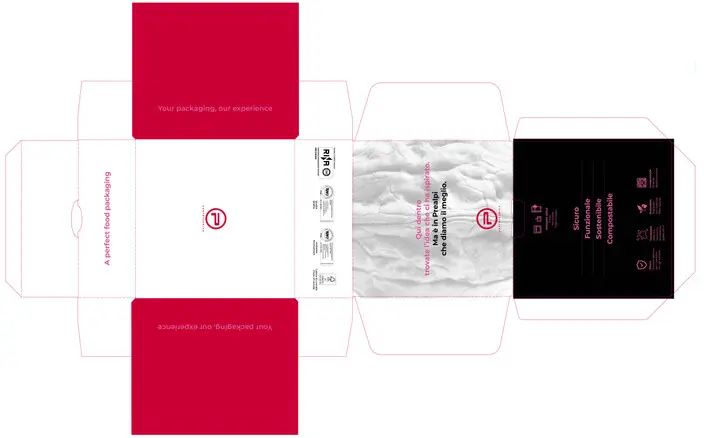

The graphics office, when called upon, can be considered the "tailor's shop" of Prealpi. It is the place where specialists in the use of cutting-edge graphic programs skillfully "dress" the prototype, suggesting possible enhancements and graphic applications that give the packaging the right appeal. They can verify the entire project, including a 3D simulation.

The design which has taken shape and bloomed into colour enters the production cycle where printing comes into play. This can involve up to 8 colours with finishing varnishes of all kinds, both water-based and UV, on a 70x100 sheet, or up to 5 colours with water-based finishes on a 100x140 format.

From the printed sheet, we move to automatic die-cutting machines where, in addition to cutting the shape, a series of processes can be performed, ranging from easy opening solutions to embossing and debossing of various shapes and sizes, both two-dimensional and three-dimensional, always in medium and

large formats. If the cases need to be glued on automatic lines or have transparent windows applied, it is possible in this phase to separate and clean each individual case from waste.

Finally, the technical office indicates the type of closure for the packaging, which can be self-assembling or glued. In the latter case, it is processed on high-speed gluing lines with 100% quality control equipment for production and automatic boxing.

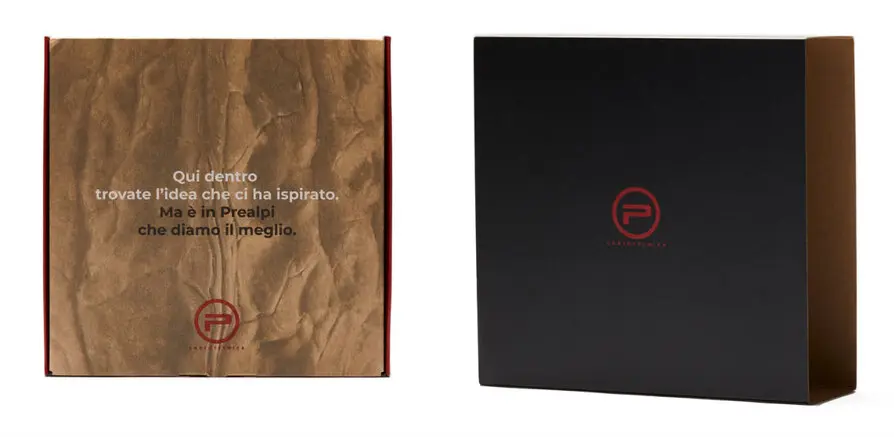

Prealpi aims to promote a philosophy of packaging that is as environmentally sustainable as possible. In a period when some materials are being banned for environmental reasons, the idea is to liken our project to what closely resembles it in nature: the shell of a nut – a "container" that is safe, functional, sustainable, and compostable.

Thus, a "representative" box is created, crafted from biodegradable and compostable materials. Its design recalls the shell of a nut, thanks to a 3D relief which to the touch brings the shell to mind, and a sampling of materials that can be used to achieve the sustainability goals inherent in the message.

We shape ideas with creativity and expertise.